Change log:

2020.04.24 17:12pst: Page created

Status: Although based upon functional designs, the material and molds below have not yet been tested.

I’ve been producing Budmen style face shields via All Bay Area PPE/Bay Area Medical Face Shield Emergency Production on a CNC using 0.5” HDPE. I wanted to find ways to scale up production without the need for specialized equipment or skills. After seeing a Smooth-On video for creating face masks from cast molds, I decided to look at producing these for the visor portion of face shields as well. I think this process could be applied to other CNC produced items with relative ease that could assist in scaling production. (This process could also potentially work well for 3D printed items).

This is a work in progress, and I’m posting the outline of my process here for others to learn from and iterate.

CAD Mold Positive

Create a 3D (or 2.5d) model to be cut on CNC for the mold positive. This allows precise layouts for CNC’d designs as well as an even flat bottom surface (top of mold). CNC isn’t required and this process could also be done with a clay bed. However, this form can also be distributed to others for further mold creation.

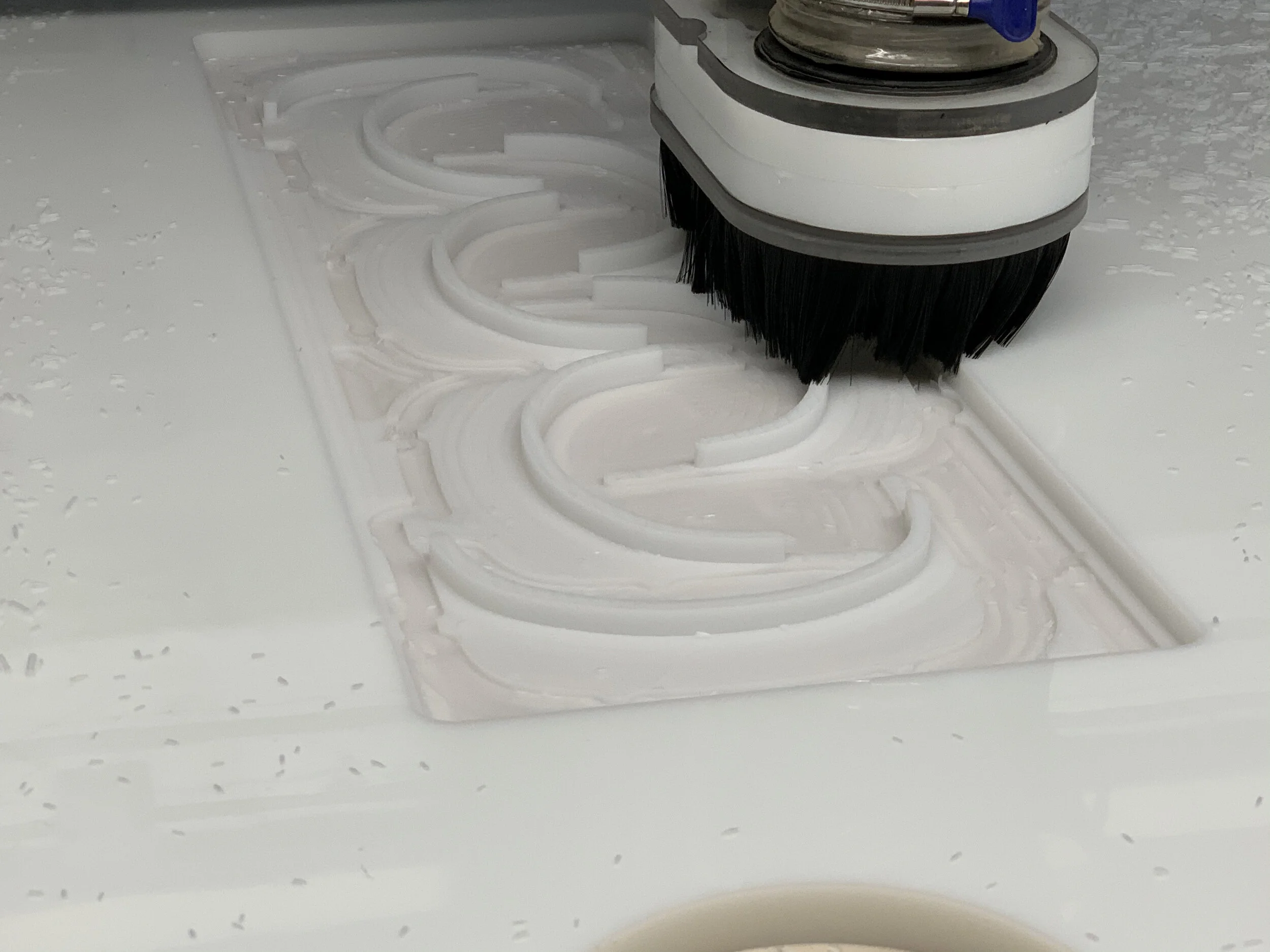

CNC Material

We used HDPE but one could use any type of material as long as it’s compatible with the mold material being used.

Finished CNC positive

A finished CNC mold positive can be attached to a rigid MDF or other plane surface as shown here. The HDPE material we used was 0.75” thick, with very thin bottoms and could use extra rigidity as the HDPE was not perfectly level.

This mold positive could be provided to others without CNC capability to begin their mold making processes with little to no special equipment required.

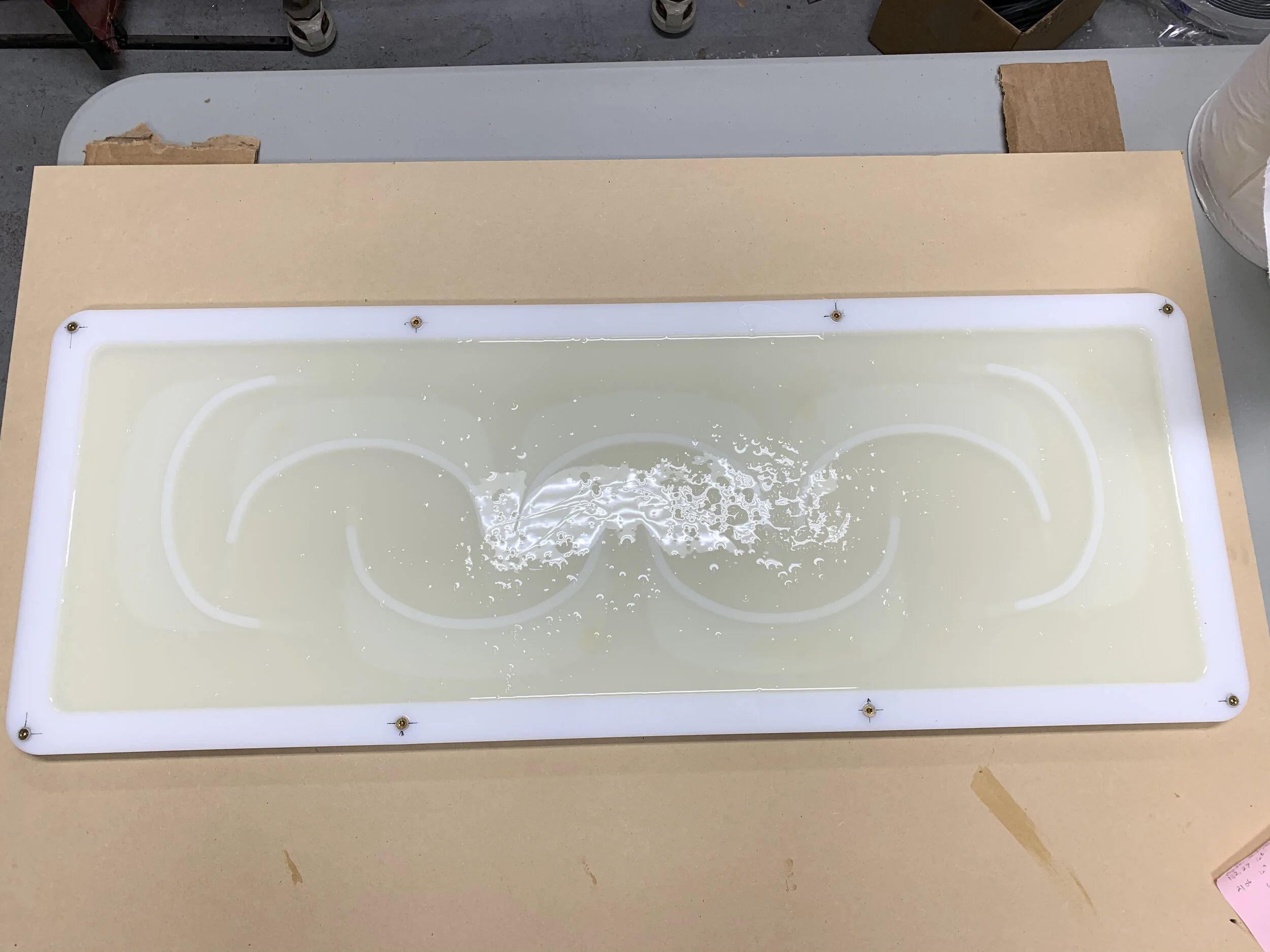

Create Mold

We used Smooth-on’s eco-flex 00-30 and eco-flex 00-35 materials (cure time differences of 5 minutes versus 4 hours).

Finished Mold

The finished mold is removed from the CNC positive. This process can be repeated as many times as needed to scale up production needs.

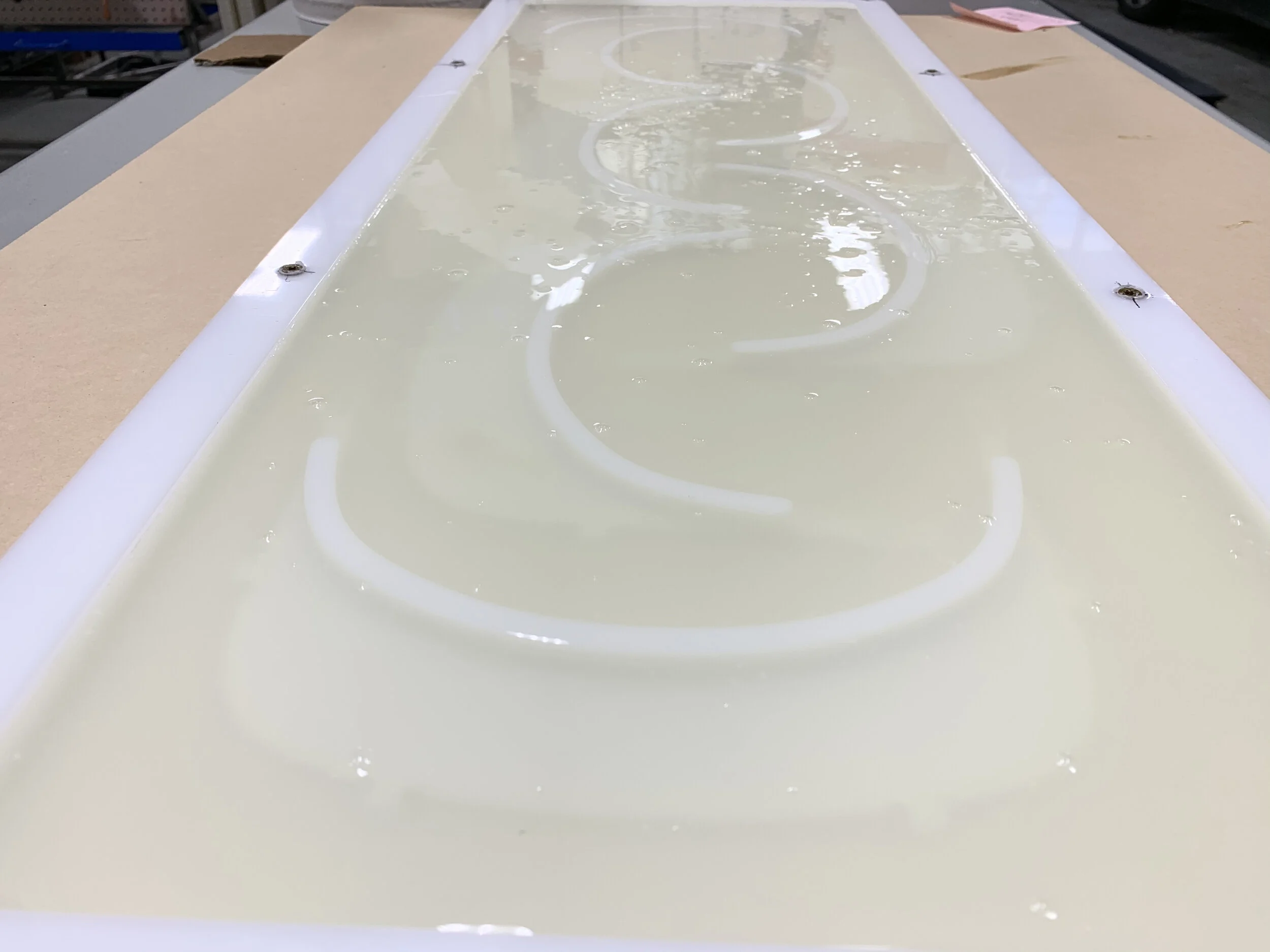

Cast Resin

For production, casting material is poured into the mold, cured, and removed to produce the final product.

In this case, we used Smooth-on Task 8 material with a 15-min cure time for fast turn-around. (It may be possible to auto-clave this material).

Links and References

Smooth-On mold and resin materials:

Eco-flex 00-30 and Eco-flex 00-35 mold making materials

Task 8 resin

Budmen face shield page (we used a derivative of this model for CNC production)

CAD/CAM Files (not tested, please evaluate for your equipment, needs, and capabilities)

Some Basic Calculations

Mold volume: 182.27 in3

Part volume: 21.06 in3

Required Eco-Flex 00-30/00-35 material required: 2,812g

7,260g = $196.58 ($0.027/g)

Required Task 8 material required: 376g

7,480g = $84.57 ($0.0113/g)

Initial 7-gang mold cost: $75.92

Per unit casting cost: $0.61

Task 8 pot life: 2.5 minutes

Task 8 cure time: 15 minutes